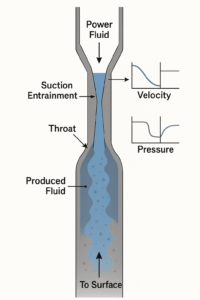

In a jet pump artificial lift system, the fluid dynamics are the heart of how lift is achieved. At its core, the system uses the Venturi effect—a high-velocity jet of power fluid entrains and lifts produced fluid from the reservoir. Here’s how the flow physics break down:

1. Nozzle Acceleration

The surface pump pressurizes the power fluid (water, treated produced water, or oil) and sends it downhole through tubing or annulus to the jet pump.

- In the nozzle, the power fluid’s pressure energy is converted into velocity.

- This creates a high-velocity jet stream exiting into the throat section.

- The governing principle here is Bernoulli’s law: pressure drops as velocity increases.

2. Suction Entrainment

The low pressure at the nozzle exit (caused by acceleration) induces a suction effect.

- This suction draws the formation fluid (produced oil, gas-cut liquid, or water) into the pump body.

- Entrainment occurs at the nozzle–throat interface, where the jet shears and mixes with reservoir fluid.

- The ratio of nozzle area to throat area (N/T ratio) controls how much reservoir fluid can be drawn in for a given jet velocity.

3. Mixing in the Throat

In the throat, power fluid and produced fluid mix turbulently.

The high-momentum jet transfers kinetic energy to the produced fluid.

Mixing equalizes velocities, but at the expense of some energy loss (turbulent dissipation).

4. Diffuser Pressure Recovery

After mixing, the two-phase stream passes into the diffuser.

- The diffuser gradually increases cross-sectional area, decelerating the flow.

- By Bernoulli’s principle, velocity decreases and pressure is recovered.

- This recovered pressure must exceed the hydrostatic head and friction in the production conduit to lift fluid to surface.

5. Surface Separation & Recycle

At the surface:

- The mixture is separated in a power-fluid separator.

- Produced fluid goes to sales or treatment.

- Clean power fluid is filtered, pressurized again by the surface pump, and recirculated downhole.

6. Key Governing Parameters

- Nozzle–throat ratio: Determines entrainment capacity and efficiency.

- Power fluid pressure & flow: Must balance hydrostatic head, tubing friction, and reservoir inflow.

- Density & viscosity of fluids: Affect jet momentum transfer, mixing efficiency, and energy losses.

- Backpressure at surface: Controls diffuser performance and stability.

- Gas content: Free gas in either power fluid or produced fluid reduces efficiency and may cause cavitation.

7. Efficiency Considerations

- Jet pumps typically achieve 20–35% hydraulic efficiency, lower than mechanical pumps, but they are prized for reliability, no moving downhole parts, and flexibility.

- Efficiency depends on operating in the right envelope of nozzle pressure, flow rate, and throat sizing.

- Too high a nozzle pressure → erosion and wasted energy.

- Too low a nozzle pressure → poor entrainment and low lift.

Simplified Energy Picture

- Surface pump: Converts mechanical shaft power → hydraulic energy in power fluid.

- Nozzle: Converts pressure → velocity (kinetic energy).

- Throat: Transfers kinetic energy → entrains produced fluid.

- Diffuser: Converts velocity → pressure (recoverable lift).