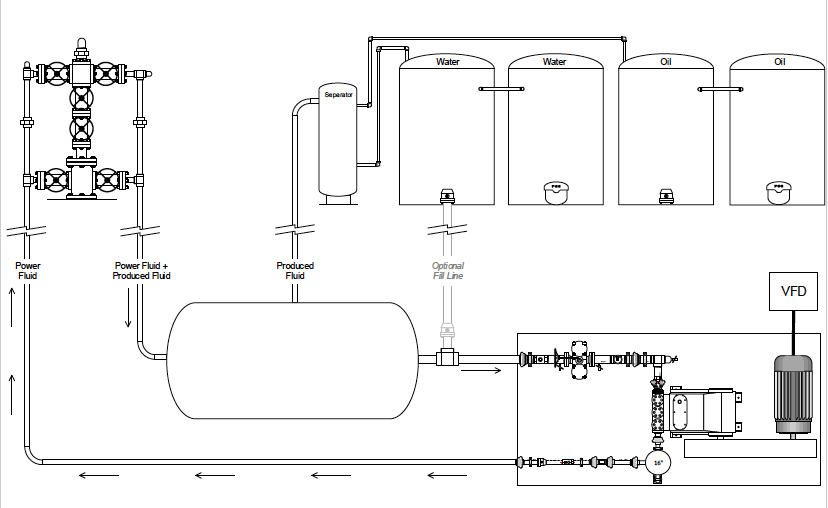

A power fluid vessel is a critical part of any jet pump surface system. Its purpose is to stabilize incoming well returns, and condition power fluid to supply the surface pump with a steady, bubble-free stream. Correct installation and placement directly influence jet pump performance and system reliability. This guide summarizes the key requirements and best practices shown throughout the installation diagrams and instructions in the reference document provided.

Configuring the Power Fluid Vessel

Several requirements support safe and stable operation:

- The vessel should allow maximum gas breakout, with a common reference size of approximately 6’ × 10’.

- Placement should be as close to the surface pump skid as possible to minimize suction losses.

- The pump suction valve must be full port to avoid introducing restrictions.

- All valves connected to the vessel must be rated at or above the maximum operating pressure.

- Well returns should enter the vessel as far from the pump suction outlet as possible to reduce turbulence and entrained gas.

- The vessel must have a pressure safety valve (PSV) rated no higher than the vessel’s working pressure and the pressure rating of all components between the vessel and the surface pump.

- The vessel PSV should discharge to the atmosphere or a safe containment system.

These conditions ensure that incoming multiphase flow transitions into a stable power fluid supply.

Suction Piping Requirements

Suction piping must be equal to or larger than the surface pump inlet diameter.

- Keep suction piping short and direct.

- Maintain a maximum velocity of 3 ft/sec to reduce friction and prevent air entrainment.

- Use sweeping elbows, long-radius bends or 45-degree fittings.

- Avoid 90-degree elbows whenever possible.

- All valves between vessel and pump should be “full-port.”

- A suction header should never supply more than one surface pump unless specifically engineered to do so.

- Typical NPSHa should be 20 ft or more to protect surface pump from premature failures.

These measures provide the smooth, unrestricted flow the pump requires.

Discharge Piping and Pump Skid Placement

Discharge piping must follow similar principles, including:

- A rating at or above the maximum pump discharge pressure

- Internal diameters that match or exceed the pump skid piping

- Sweeping elbows to reduce pressure loss in piping.

- A pulsation dampener (optional) can help with discharge pipe vibrations.

Pump skid placement should be:

- As near to the power fluid source as possible

- On a firm, level surface

- Within secondary containment if available

This minimizes suction head losses and improves operational safety.

Pressure Safety Valve Installation (Surface Pump)

- The PSV must be set no more than 10% above maximum pump pressure.

- The PSV must be sized for the maximum pump volume without exceeding allowable system pressure.

- No valves may be installed in PSV piping, as this would create a blockage risk.

- PSV discharge should go to atmosphere or a safe containment system

- The PSV must never be piped into suction plumbing.

Following these rules ensures safe operation during unexpected pressure events.

A System Built on Fluid Stability

A properly installed power fluid vessel safeguards the jet pump system by ensuring stable suction conditions, effective gas separation and safe pressure management. Pairing correct vessel installation with appropriate wellhead configurations creates a reliable foundation for jet pump operation.