Install & Operate

Follow proven methods for installing and operating jet pump systems. This section outlines field-tested procedures and checklists that promote reliability and performance.

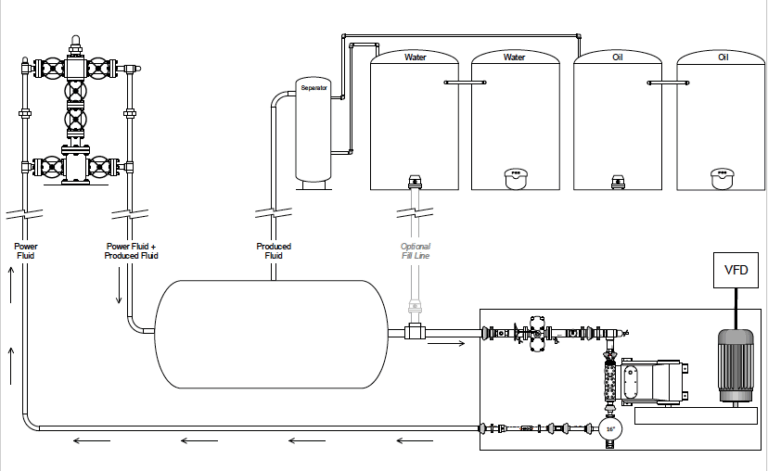

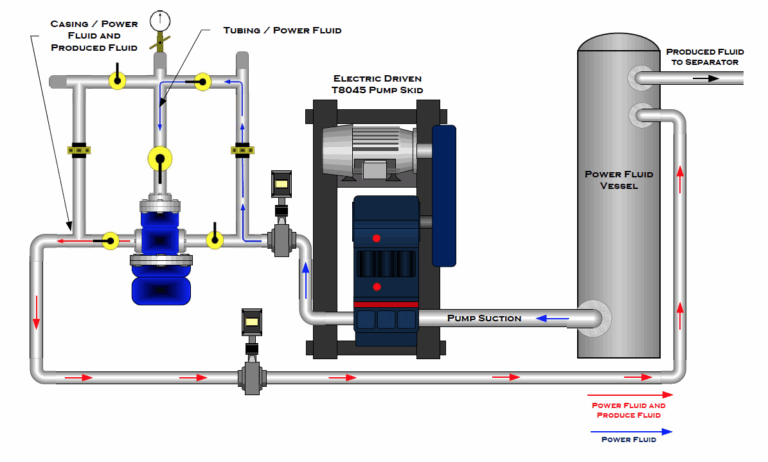

Installing a Power Fluid Vessel for Jet Pump Operations

A power fluid vessel is a critical part of any jet pump surface system. Its purpose is to stabilize incoming well returns, and condition power fluid to supply the surface pump with a steady, bubble-free stream. Correct installation and placement…

Installing a 2.5-Inch Jet Pump System: Normal and Reverse Flow

Jet pump installations require precise handling of downhole equipment, tubing paths, and surface circulation systems. These pumps are designed to operate in both normal-flow and reverse-flow configurations, offering flexibility for wells with varying production profiles, tubing constraints, or surface facility…

Installing and Operating a Reverse-Flow Jet Pump System

Reverse-flow jet pump systems offer a flexible way to lift fluids in wells where conventional circulation paths or flow geometries create operational constraints. This configuration redirects the return path of power fluid and produced fluids, allowing the pump to function…

Power Fluid Considerations for Jet Pump

In hydraulic jet pump artificial lift systems, the choice and management of power fluid are just as critical as pump design or well configuration. Power fluid acts as both the energy source and the medium that drives the Venturi-based lift…

Downhole Installation Best Practices for Jet Pump Artificial Lift

Overview Jet pumps are widely used in artificial lift due to their flexibility, reliability and durability. With no moving parts downhole, their mechanical simplicity is advantageous, but achieving maximum run life and efficiency requires meticulous installation. Proper tubing configuration, jet…